Visual Work Instructions provide your users with step-by-step instructions for completing inspections. With PSI you can input information about the inspection, upload pictures, videos, pdfs, and other supporting documents to give your employees the knowledge they need to get the job done right. This allows you to keep all of your instructions organized and accessible, so that the entire team is always on the same page about how a process should be completed. You can update this information simply and instantly, helping to mitigate confusion about whether your team has a current version of the instructions.

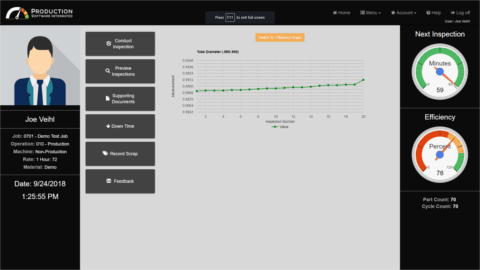

Streamline your inspection process by collecting inspection results right on-screen alongside the corresponding work instruction. PSI provides your inspectors with a simple platform to log their inspections, all while showing them exactly how the inspection should be performed, which increases the accuracy of the inspections, eliminates the need for paper logs, and simplifies the process for your inspectors and quality control managers.

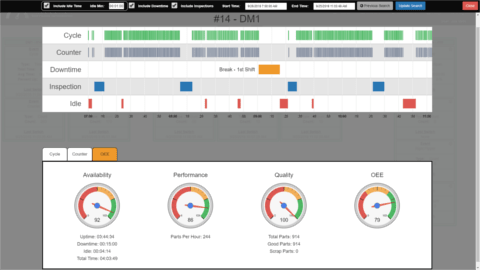

Easily monitor performance with an on-screen efficiency graph and gage. Calculate whether an operator has been processing an efficient number of parts for the job they are working on, based on the target production rates and the inspection data that has been gathered, and see the results right on the production page in both graph and gage format.

With time-driven inspection prompts you can alert users on-screen when they are due to perform an inspection. A visual countdown shown on-screen between inspections allows your operators to monitor how much time they have left until they need to perform another inspection--and passing supervisors can see at-a-glance if an operator is on-time or over-due.

With our Quality Alert system, you can make sure that crucial information is brought to the attention of your operators when they start a job or prior to each inspection. Operators must confirm that they have seen the alert and records are kept to indicate when they saw it.

Take your inspection data and turn it into useful reports to gain insights to your company's quality and efficiency with the reports generator. Generate reports on production, inspection values, training, downtime, scrap, and more. Modify your search parameters so you can focus on the information that you need. You can also export reports to CSV, Excel, or PDF format.

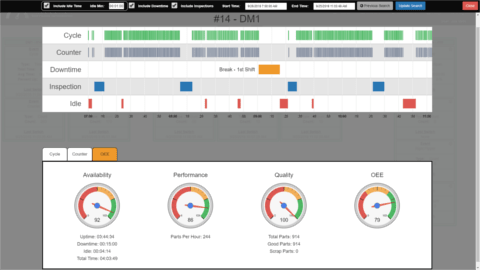

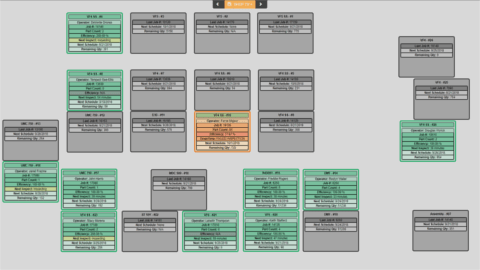

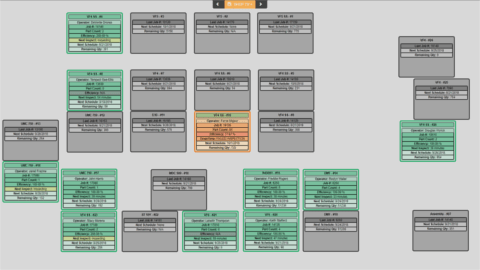

Easily monitor machines and jobs in real-time with the Dashboard system. Get up-to-date information about all your machines and jobs being run. We use a color coded system so you can easily tell which machines are running or in down-time, whether your operators are meeting their target efficiency rates, and whether they are on-time or overdue for an inspection. You can even customize your dashboard so the layout mimics your shop floor.

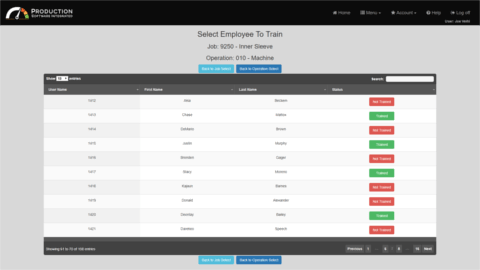

Set training requirements for each job, to ensure you have the right person on the job, and establish accountability. You can see how many hours of training a user has logged, who the trainer is, and keep operators from running jobs by themselves until they have completed the required amount of hours and have been approved by their trainer.

Stay up-to-date on gage calibration and ensure that your team is always working with the right tools for every job. Input your gages into our Gage Calibration System to automatically disable the ability to run inspections when an attached gage has reached its calibration expiration, and notify the user that they are out of calibration. You can even create calibration inspections to calibrate your gages.

Record and track important job data, giving you the ability to quickly spot and correct errors as soon as they arise. Be able to easily track who had their hands on a job, and exactly what was done. Meet compliance standards by showing accountability and control over every process.

Connect our machine monitoring device to any machine on your shop floor so you can track machine uptime and reduce downtime. Combined with operator efficency and scrap tracking, we can calculate OEE so you can see how effective your processes are.